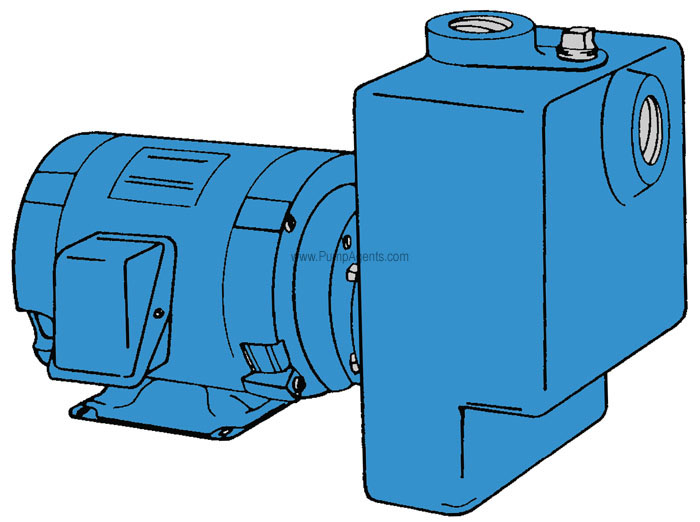

Burks # 3100WG6-2-MV Self Priming Centrifugal Pump 10 HP

Burks # 3100WG6-2-MV

Burks catalog # 3100WG6-2-MV, Self Priming Centrifugal Pump and Motor unit. Cast Iron Construction, with a Bronze Impeller and Viton/Carbon/Ceramic/SS Mechanical Seal. Pump is close coupled to a 10 Horsepower, 3500 RPM, 230/460 Volts, Three Phase, ODP Open Drip Proof Motor. Ports are 2 Inch NPT Inlet, 2 Inch NPT Outlet.

Price : $ 9711.29

Product Information :

The Burks 3100WG6-2-MV is a Cast Iron Self Priming Centrifugal Pump with a Bronze Impeller, Viton/Carbon/Ceramic/SS Mechanical Seal, 2 Inch NPT Inlet, 2 Inch NPT Outlet Ports, close coupled to a 10 Horsepower, 3500 RPM, 230/460 Volts, 3 Phase, ODP Open Drip Proof, 60Hz Motor. This pump has a Maximum flow rate of up to 260 gallons per minute water flow at 60 feet of head and is self-priming with a suction lift of 10 feet without a foot or check valve (25 foot suction lift using a foot or check valve and a filled inlet line). Be sure suction lines are airtight or pump will not self-prime. This pump is the non-standard Viton seal version, which is used in this pump for higher temperatures, and chemical resistance. The Viton fluoroelastomer is a good Solvent Mechanical Seal and can be used for oils, fuels, lubricants, most mineral acids, and many solvents that attack other rubbers such as Carbon Tetrachloride, toluene, benzene, and xylene. This line of Burks Self-Priming Centrifugal pumps is designed for industrial and commercial applications requiring high volume liquid transfer, waste water drainage and chemical processing. These pumps feature an Enclosed Bronze Impeller, and Viton seals for water and other fluids with specific gravities of 1. 00 S. G. The motor on this pump is a JM Type motor and has a NEMA standard mounting flange, extended steel shaft and dual bearings. These motors offer the advantage of quiet operation, controlled shaft deflection for longer seal life, and bearings sized to provide good service life. All motors must be installed with a magnetic starter which provides full 3-leg protection. Failure to use correct starter and overloads will void motor warranty. These Self Priming Pumps require very little attention, resulting in significant savings of maintenance time and money and making them a sensible solution for industrial and municipal applications. While this pump can be run dry for short periods of time, a lack of liquid will damage the Mechanical seal. Self priming centrifugal pumps must be operated in the horizontal position. Centrifugal pumps are designed for single rotation and are non reversible. Standard rotation is counter clockwise looking at the pump inlet port (clockwise facing pump shaft). The wetted material in contact with the liquid are Cast Iron, Bronze, 303 Stainless Steel, and Viton. The dimensions of this pump are 24-1/2 inches long, 14-1/4 inches high, and 16 inches wide (including motor junction box).

WEIGHT : This pump and motor unit weighs 215 Lbs.

Features :

Product Specs :

Rugged Bronze-Fitted Cast Iron Construction

Leakproof Mechanical Shaft Seal

Stainless Steel Shaft with Bronze shaft sleeve protects shaft from wear and corrosion.

Back Pull-Out Design For Easy Servicing

Self-Priming, Once Case is Filled With Fluid

Diaphragms, Flappers or Check Valves Are Not Required In Pump Suction Piping. But Are Recommended

EVERY pump is factory tested and will meet Hydraulic Institute standards.

Parts and Accessories for Burks model 3100WG6-2-MV

Applications

This is a robust, longlife Cast Iron, General Purpose, Self Priming Centrifugal pump, with high efficiency and flow, designed specifically for the industrial, agricultural, marine and home end user markets. Typical Applications for this pump are Lawn Sprinkling, Pressure Boosting, Sprinkler Systems, Light Irrigation, Dewatering clean liquids, and Transfer from underground storage. SUCTION LIFT PRIMING A foot valve should be used for priming on suction lift applications. The foot valve, located at the end or foot of the suction piping, functions as a check valve and allows flow in one direction only, toward the pump. Otherwise, all the liquid will drain from the pump and suction piping back into the sump after shutdown. Initial priming is accomplished by completely filling the suction piping and pump casing with the liquid to be pumped. This can be done by removing the priming plug at the top of the pump casing, and inserting a pipe nipple in the orifice with an appropriate increaser to accommodate a hose connection. A priming line can also be inserted in the discharge piping between the check valve and the pump, or the priming can be done with a bucket and funnel. The important thing is to completely fill the suction pipe and pump casing with liquid. When the pump is started, the vacuum created by pumping the priming fluid, combined with atmospheric pressure in the liquid well, forces liquid into the suction piping, thus opening the valve and keeping it open until the pump is shut down. When the pump is shut down, the liquid being pumped reverses its flow causing the valve to close. The liquid is now trapped in the suction piping and pump casing, thus maintaining a prime on the pump.