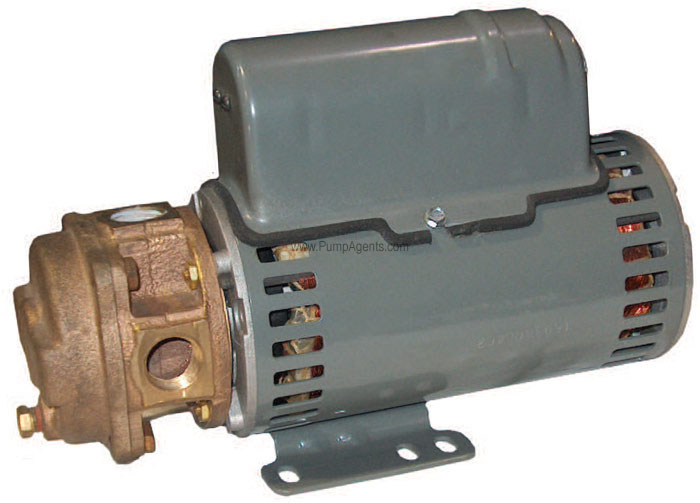

Burks # A3CR6MV-FE Close Coupled Turbine Pump and FE Motor - Viton Seal version

Burks # A3CR6MV-FE

Burks catalog # A3CR6MV-FE, Close Coupled Turbine Pump and FE Motor and Motor unit. Bronze Construction, with a Bronze Impeller and Viton/Carbon/Ceramic/SS Mechanical Seal. Pump is close coupled to a 1/3 Horsepower, 3500 RPM, 115 Volt, Single Phase Motor. Ports are 1/2 Inch NPT Inlet, 1/2 Inch NPT Outlet.

Price : $ 2755.62

Product Information :

The Burks A3CR6MV-FE is a Bronze Close Coupled Turbine Pump and FE Motor with a Bronze Impeller, Viton/Carbon/Ceramic/SS Mechanical Seal, 1/2 Inch NPT Inlet, 1/2 Inch NPT Outlet Ports, close coupled to a 1/3 Horsepower, 3500 RPM, 115 Volt, 1 Phase, 60Hz Motor. This pump has a maximum performance of up to 2. 9 gallons per minute water flow at 175 feet of head (75 PSI). The motor on this pump has ball bearing construction and an open ventilated enclosure which is NOT drip-proof. It is rated for continuous duty operation at all ratings shown, and furnished with a UL Recongnized motor lead. This pump is the non-standard Viton seal version, which is used in this pump for higher temperatures, and chemical resistance. It also has the non-standard -FE motor which is the OEM version. This compact turbine pump is designed for pumping clear water and many other nonabrasive, lower viscosity liquids on high pressure, low capacity applications with the greatest possible efficiency. The Bronze impeller with Monel blades is the only moving part and the Bronze raceway with cast-in vortex pockets will not vapor lock. This pump's unique design is engineered for many applications requiring higher pressures and lower capacities impossible for other single stage pumps of a similar size, and the pump's compact space-saving size without a coupling eliminates misalignment problems. The operating temperature limits of this pump depend on the impeller type and the standard Bronze impeller in this pump is suitable for fluid temperatures to 250 degrees F (121 degrees C). The pump shaft seal is a mechanical seal with ceramic seat and carbon seal face for maximum durability, and long trouble-free service. While this pump can be run dry for short periods of time, a lack of liquid will damage the Mechanical seal. The wetted material in contact with the liquid are Bronze, 303 Stainless Steel, and Viton. The dimensions of this pump are 10-1/2 inches long, 6-1/4 inches high, and 4 inches wide.

WEIGHT : This pump and motor unit weighs 17 Lbs.

NOTE: A strainer, approximately 20 mesh, should be installed on the suction side of the pump to prevent chips, scale or hard foreign particles from entering the pump and damaging the raceway and impeller.

Features :

Product Specs :

Raceway Sealing grooves, machined into the face of the raceway, match the impeller sealing grooves, minimizing water slippage and increasing delivery efficiencies.

Impeller Annular grooves or sealing rings, machined into the face of the impeller are perfectly matched with corresponding grooves in the raceway and intermesh without metal-to-metal contact to form a labyrinth seal.

Parts and Accessories for Burks model A3CR6MV-FE

Applications

Designed for versatile, high performance applications these Burks CR series Turbine Pumps are designed for pumping any clean, noncorrosive, nonabrasive lower viscosity liquid on low flow, highhead applications. They are used is a wide range of industries on applications such as SemiConductor Manufacturing applications, Carpet Cleaning Machines, Small Steam Generators, Solar Heating Systems, Booster Pump, Injector Venturi Operation, Cleaning and Flushing, Low Flow Circulating, Spray Nozzles, Liquid Transfer, Coolant Pump, and Aeration applications. These are just a few of the most common applications. The durable materials of construction, long service life, and low maintenance design make the Burks CR Turbine Pump an excellent choice for numerous clean water applications. These pumps are designed for low maintenance and long service life. To operate the pump the raceway conducts fluid into the impeller and then provides a channel for the liquid to move as it is propelled and energized by the impeller. The Burks Regenerative Turbine Pump is unique in design and is engineered for high pressure, low flow applications. Burks Turbine Pumps are of the positive displacement type. When the pump is operating, liquid will be delivered to the discharge side of the pump. If the discharge line is blocked or closed, pressure will build up until the motor stalls, a pump part breaks or the piping bursts. To prevent the possibility of equipment damage or personal injury, a pressure relieving device of adequate size must be incorporated in the discharge side of the system. NOTE A strainer, approximately 20 mesh, should be installed on the suction side of the pump to prevent chips, scale or hard foreign particles from entering the pump and damaging the raceway and impeller.