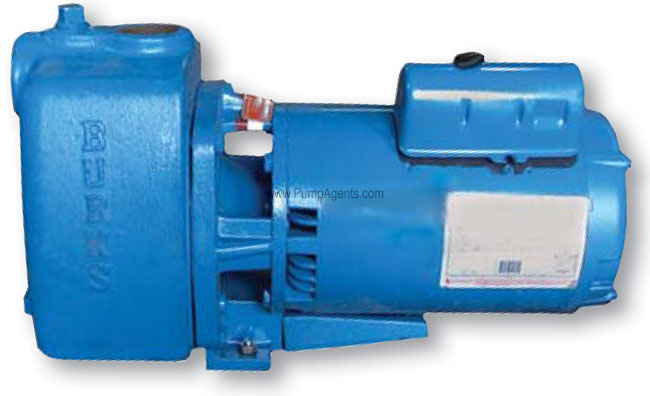

Burks # T320WA6 Self Priming Centrifugal Pump 2 HP

Burks # T320WA6

Burks catalog # T320WA6, Self Priming Centrifugal Pump and Motor unit. Cast Iron Construction, with a Noryl Plastic Impeller and Buna/N/Carbon/Ceramic/SS Mechanical Seal. Pump is close coupled to a 2 Horsepower, 3500 RPM, 208-230/460 Volts, Three Phase, TEFC Totally Enclosed Fan Cooled Motor. Ports are 1-1/2 Inch NPT Inlet, 1-1/2 Inch NPT Outlet.

Price : $ 3296.85

Product Information :

The Burks T320WA6 is a Cast Iron Self Priming Centrifugal Pump with a Noryl Plastic Impeller, Buna-N/Carbon/Ceramic/SS Mechanical Seal, 1-1/2 Inch NPT Inlet Port, 1-1/2 Inch NPT Outlet Port, coupled to a 2 Horsepower, 3500 RPM, 208-230/460 Volts, 3 Phase, TEFC Totally Enclosed Fan Cooled, 60Hz Motor. This pump has a Maximum flow rate of up to 73 gallons per minute water flow at 20 PSI and is self-priming with a suction lift of 10 feet without a foot or check valve (25 foot suction lift using a foot or check valve and a filled inlet line). Be sure suction lines are airtight or pump will not self-prime. A 3/4 Inch pipe plug on the tank top is for initial filling of priming chamber and inlet line and pump priming is automatic thereafter. The operating temperature limits of this pump depend on the impeller compound. The following range applies for Noryl Plastic impellers : 175 degrees F (80 degrees C). These Self Priming Pumps require very little attention, resulting in significant savings of maintenance time and money and making them a sensible solution for industrial and municipal applications. While this pump can be run dry for short periods of time, a lack of liquid will damage the Mechanical seal and the plastic pump components. Self priming centrifugal pumps must be operated in the horizontal position. Centrifugal pumps are designed for single rotation and are non reversible. Standard rotation is counter clockwise looking at the pump inlet port (clockwise facing pump shaft). The wetted materials in contact with the liquid are Cast Iron, Brass, 303 Stainless Steel, and Buna-N. The dimensions of this pump are 19-1/8 inches long, 10 inches high, and 8 inches wide. All three phase motors and all explosion proof motors must be installed with a magnetic starter which provides full 3-leg protection.

Features :

Product Specs :

Fast Priming pumps stays primed. Flapper and check valves on suction pipe are not required, but are recommended.

Non-overloading performance at all catalog ratings.

Continuous duty motor.

Leak Proof mechanical shaft seal - self adjusting

Cast Iron Casing with suction, discharge, prime, vacuum gauge and drain tappings.

Glass filled Noryl enclosed impeller with molded-in brass insert.

Every pump is factory tested and will meet Hydraulic Institute standards.

Parts and Accessories for Burks model T320WA6

Applications

This is a robust, longlife Cast Iron, General Purpose, Self Priming Centrifugal pump, with high efficiency and flow, designed specifically for the industrial, agricultural, marine and home end user markets. Typical Applications for this pump are Lawn Sprinkling, Pressure Boosting, Sprinkler Systems, Light Irrigation, Dewatering clean liquids, and Transfer from underground storage. SUCTION LIFT PRIMING A foot valve should be used for priming on suction lift applications. The foot valve, located at the end or foot of the suction piping, functions as a check valve and allows flow in one direction only, toward the pump. Otherwise, all the liquid will drain from the pump and suction piping back into the sump after shutdown. Initial priming is accomplished by completely filling the suction piping and pump casing with the liquid to be pumped. This can be done by removing the priming plug at the top of the pump casing, and inserting a pipe nipple in the orifice with an appropriate increaser to accommodate a hose connection. A priming line can also be inserted in the discharge piping between the check valve and the pump, or the priming can be done with a bucket and funnel. The important thing is to completely fill the suction pipe and pump casing with liquid. When the pump is started, the vacuum created by pumping the priming fluid, combined with atmospheric pressure in the liquid well, forces liquid into the suction piping, thus opening the valve and keeping it open until the pump is shut down. When the pump is shut down, the liquid being pumped reverses its flow causing the valve to close. The liquid is now trapped in the suction piping and pump casing, thus maintaining a prime on the pump.