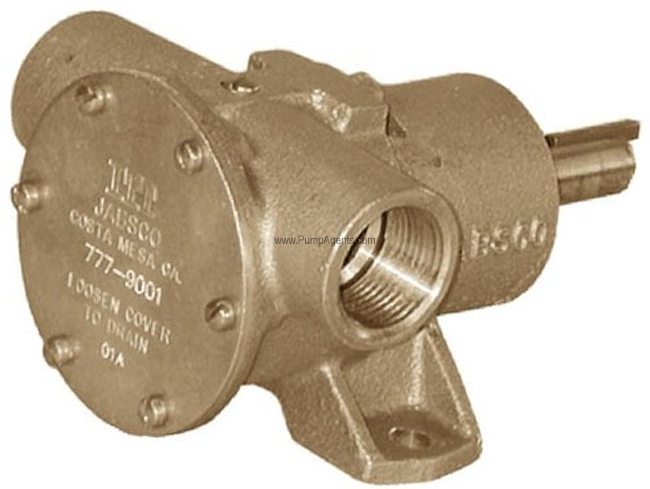

Jabsco # 777-0001 Bronze Flexible Impeller Pump

Product Information :

The Jabsco 777-0001 is a bronze Flexible Impeller pump with a Neoprene Impeller, Lip Type seal, 1 Inch NPT Internal Ports, bare shafted pedestal pump end only without a Motor. The Neoprene impeller in this pump is good for water and general-purpose pumping. Temperature limits for Neoprene impellers are 45 degrees F to 180 degrees F ( 7 degrees C to 82 degrees C). This pump has a nominal flow rate of 23 GPM (87 LPM) at 1750 RPM, and is self-priming from dry up to 10 feet (3m) and primes at low or high speeds. For vertical lift of 10 feet, a minimum of 800 RPM is required. Pump will produce suction lift of up to 22 feet (6.7m) when wetted. Be sure suction lines are airtight or pump will not self-prime. This flexible impeller pump combines the priming feature of positive displacement type pumps with the general transfer ability of centrifugals. It will pump either thin or viscous liquids and can handle more solids in suspension than other types of rotary pumps. Pump may be mounted in any position. The rotation of the pump shaft determines the location of the pump's intake and discharge ports. Pump is normally assembled at factory for clockwise rotation (looking at end cover). This unit depends on liquid pumped for lubrication. Do Not Run Dry for more than 30 seconds. Lack of liquid will damage the impeller and the pump components.

Features :

Product Specs :

23 GPM .

10' dry prime, 22' wet prime.

Bronze pedestal.

Constructed from marine quality bronze and stainless steel.

Handles hard and soft solids without clogging.

Will tolerate abrasive wear.

Can pump in either direction.

Will not airlock.

Easy to service and maintain.

Parts and Accessories for Jabsco model 777-0001

Major Overhaul Kit / Rebuild Kit :

Catalog # 90010-0001, Service Kit, Neoprene, with Neoprene Impeller, O-Ring and Lip Seal

Price: $ 119.56

Impeller :

Catalog # 17937-0001, Impeller, Neoprene

Price: $ 42.67

Applications

Operating in either direction, with flows up to 23 GPM this flexible impeller pump is ideally suited to washdown, circulation and fire duty applications onboard or dockside. Where needed, these pumps have easily replaced cams, end covers and wearplates for extended product life.

Marine applications for this pump include Engine Cooling, Pump bilge, Washdowns, Circulating water in bait tanks, Utility dockside pump. Industrial applications for this pump include Circulating and transferring, Velocity mixing, Pumping machine tool coolants, Return spill, Sump drainage, Chemicals, Pharmaceuticals, Soap, Liquors, Ink, Dyes, Alcohol, Dilute acids, Tanning Liquors, Glycerine, Brine, etc. This pump can also be used for Pumping water for stock, Pumping water from shallow wells and cisterns, Pumping liquid ballast into tractor tires, Pumping out flooded basements, Cesspools, Sumps, Water heaters and water closets, Drains and sinks, Draining fishponds and pools.

Do not pump light fraction petroleum derivatives, solvents, thinners, highly concentrated or organic acids. Damage to pump may result.