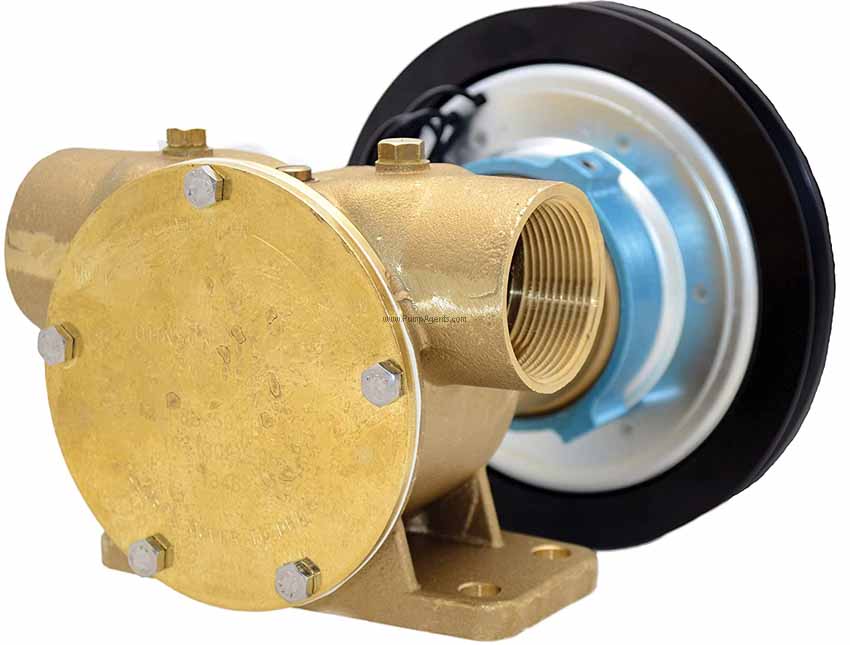

Johnson # 10-13022-33 Electro-Magnetic Clutch Pump

Johnson # 10-13022-33

Johnson catalog # 10-13022-33, Electro-Magnetic Clutch Pump and 12 VDC Clutch unit, F8B-50017 series, with 7 inch 2A pulley, Bronze construction. Inlet Port is 1-1/4 inch FNPT, Discharge Port is 1-1/4 inch FNPT. Model # F8B-50017.

Price : $ 1530.00

Product Information :

The Johnson 10-13022-33 is a Bronze Electro-Magnetic Clutch Pump and 12 VDC Clutch unit, F8B-50017 series, with 7 inch 2A pulley, with 1-1/4 inch FNPT by 1-1/4 inch FNPT Ports, replacement pump end only without a Motor. With an electro-magnetic clutch pump you will have pumping power whenever needed, at a push of a button, without being at the pump. Combined with a vacuum switch (recommended for bilge pump application), the clutch will automatically disengage whenever the pump starts priming air, thereby preventing dry running and pump damage. This flexible impeller pump is self-priming and provides an efficient solution to most raw water pumping needs. This pump can pass fairly large solids without clogging or damaging the pumps. This engine cooling pump is designed to the demands of engine manufacturers and are built to take rough treatment. This pump is constructed from marine quality bronze and stainless steel for ruggedness and reliability. This Pump has one moving part - a tough, long-lived, wear-resistant flexible impeller lubricated by the liquid being pumped. No metal-to-metal pumping action - no gears to jam, clog or become noisy. It will not air Lock - the pump will continue to operate even when air passes through the system, and it delivers a smooth even pulsation free flow. The Flexible Impeller in this pump generates high rubbing friction unless lubricated by the liquid being pumped. A lack of liquid will cause the impeller to degrade rapidly. On initial start-up pump must be primed to prevent dry-running of the impeller. This pump is self-priming, and will self-prime at low or high speeds. It will pump instantly, and a suction lift of 15 feet is possible when impeller is wet and pump fully primed. Suction lines must be air tight in order for pump to self prime. These pumps are designed to be fully serviceable and after long use can be restored to like new condition, avoiding complete pump replacement. The impeller and cam are easily replaced. The Temperature limits for the Neoprene impeller in this pump is 45 degrees F to 180 degrees F ( 7 degrees C to 82 degrees C). Pumping colder water than 45 degrees F will shorten the impeller life.

WEIGHT : The Johnson 10-13022-33 weighs 27 lbs.

Features :

Parts and Accessories for Johnson model 10-13022-33

Major Overhaul Kit / Rebuild Kit :

Catalog # 10-13022-33MJK, Major Service Kit for Johnson 10-13022-33 Contains All Internal Service Parts Except the Shaft. The Mechanical Seal in this kit will repair both the mechanical seal version and lip seal version pumps.

Price: $ 584.84

Minor Service Kit :

Catalog # 10-13022-33MNK, Minor Service Kit for Johnson 10-13022-33 Contains Impeller, Water Seal and Cover Gasket. The Mechanical Seal in this kit will repair both the mechanical seal version and lip seal version pumps.

Price: $ 186.69

Other Parts :

Catalog # 01-42424, Cover Gasket, White Foam Type

Price: $ 4.46

Applications

Typical Applications for the 101302233 pump are Marine applications such as a bilge pump, deckwash pump, washdown, emptying holding tanks, engine cooling. It can also be used in Industrial applications such as liquid circulation and transfer, emptying tanks and sump drainage, and handling of solids in suspension. This flexible impeller pump provides an efficient solution to most raw water pumping needs. The primary advantage of a flexible impeller pump is its selfpriming ability. As the vanes of the impeller are depressed and rebound, they create their own vacuum drawing fluid into the pump. A dry pump can lift water up to as much as 15 feet. Thus a flexible impeller pump being used for engine cooling needs not be located below the water line or manually primed. An added feature of flexible impeller pumps is that they can pass fairly large solids without clogging or damaging the pump. This reduces the need for filtering the incoming fluid. For general raw or fresh water applications, the standard long lasting neoprene rubber impeller is used. A general feature of all flexible impeller pumps is that they cannot be permitted to run dry for more than 30 seconds. Both the impeller and the seals depend upon the water for lubrication and will soon burn out if run dry. Wearing parts are easily replaceable, and service kits are available for all standard models. This Johnson flexible impeller pump combines the priming feature of positive displacement type pumps with the general transfer ability of centrifugals. It will pump either thin or viscous liquids and can handle more solids in suspension than other types of rotary pumps. It operates at low or high speeds can be mounted at any angle and pumps in either direction with equal efficiency.