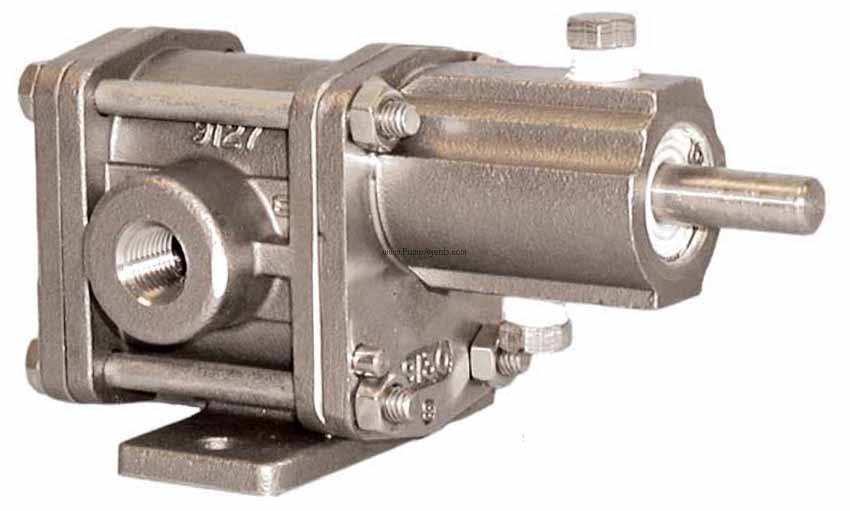

Oberdorfer # 103136C Chemsteel Gear Pump End only

Oberdorfer # 103136C

Oberdorfer catalog # 103136C, Chemsteel Gear Pump End only, with 316 Stainless Steel Housing, 316 Stainless Steel shafts, W88 Drive Gear, W88 Idle Gear, Carbon Bearings, PTFE Teflon/Graphite Packing. Inlet Port is 1/4 inch FNPT, Discharge Port is 1/4 inch FNPT.

Price : $ 631.42

Product Information :

The Oberdorfer 103136C is a Chemsteel Gear Pump End only, with 316 Stainless Steel Housing, 316 Stainless Steel shafts, W88 Drive Gear, W88 Idle Gear, Carbon Bearings, PTFE Teflon/Graphite Packing with 1/4 inch FNPT by 1/4 inch FNPT Ports, replacement pump end only without a Motor. This rotary gear pump is of the external gear positive displacement type, displacing a finite volume of fluid with each shaft revolution. As such, capacity varies in direct proportion to pump speed. This pump is rated for operation at a maximum shaft speed of 1750 RPM. This pump can handle viscous fluids to 100,000 cps (462,000 SSU) at reduced shaft speeds, with flow rates to 1.5 GPM GPM, and a suction lift capability to 20 feet (6.1 meters) for new pumps. It has rugged, three-section, o-ring sealed thru-bolt construction provides ease of servicing and parts replacement. This pump has precision investment castings of type 316 Stainless Steel which is an all purpose austenitic stainless alloy, with excellent corrosion resistance, and is the premium choice of all 300 series stainless alloys. The precision machined Helical metallic gears of W88 Stainless offer noise reduction by as much as 10db. The type W88 Alloy is a non-galling stainless alloy for "gear on gear" applications, created by alloying special rare and select materials. Metal/Metal gear combinations are limited to a maximum differential pressure of 150 PSI. This pump features slotted bearings to lubricate the shaft and gear surfaces, and hydraulic porting to balance axial thrust and to reduce wear. The Carbon sleeve bearings and are for maximum chemical resistance and high load capacity as the carbon bearings function as thrust flanges and wear plates. They are full size bearings that match the gear diameter and eliminate the need for separate wear plates. This pump is equipped with Teflon impregnated graphite packing and will require periodic adjustment to avoid excessive leakage. Eventually all the packing in the pump will become deteriorated and will have to be replaced. The o-rings are Teflon encapsulating, silicone and provide elastic memory to assure an effective long lasting seal. The upper shaft configuration lends itself to in-line pump seal maintenance without the leakage of trapped chemicals from an incompletely drained pump. Ample port sizing of 1/4 inch FNPT ports reduce the likelihood of cavitation when inlet pressure is marginal. Additionally, this pump offers bi-directional operation for applications requiring reversing flow, and will perform equally well in either direction. To change flow direction effectively reversing the suction and discharge ports, simply switch driver rotation by following motor wiring diagram instructions. The positive displacement principle requires the installation of a pressure relief valve protecting the pump against over pressure. Over pressurization can occur when a valve is closed or a blockage occurs.

Features :

Applications

Typical applications for the 103136C pump include Beverage Cooling, Brine Injection, Blending for fracking, Dosing pumps for organic and inorganic chemicals, Circulation pumps for hydraulic fluids, Underwater pumps for deep sea ocean applications, Transfer pumps for additives or alcohols or lyes or bases, and many other applications. This pump is designed to handle common and highly corrosive liquids that must be pumped under pressure. It is manufactured to an extremely precise tolerance, this pump will prevent system contamination while maintaining the purity and integrity of the liquid being pumped. Typical liquids pumped are adhesives, resins, catalysts, odor control additives, fertilizers, polymers, flocculants, caustics, hydrochloric acid, solvents, biocides, dyes, bleaching chemicals, detergents, and many more liquids. These gear pumps are frequently relied upon for product transfer. They can handle both high and low viscosity and high and low temperature fluids including liquefied gasses. The selection of this pump to fit a given application depends upon full knowledge of the application including both system parameters and fluid properties. As a metering pump, when mounted to a variable speed motor and controller, a gear pump offers several advantages over reciprocating type metering pumps. Unlike other reciprocating type pumps, gear pumps offer nonpulsating flow. Piping is simplified, because pulsation dampeners and back pressure valves are not required. Liquids, which have a tendency to gas off, create priming difficulties with the reciprocating type pumps. Since gear pumps are inherently self priming and their nonpulsating flow does not agitate the liquid, they may be better choices for these applications. To achieve successful operation and maximum life from your pump make sure that the pump is compatible with the service and operating conditions of your application. The pump materials of construction and other details are specified by the pump model number. This gear pump accepts standard NEMA 56C and 143/5TC motors. This enables the pump to be close coupled which provides greater assembled strength, complete enclosure of all moving parts, and a compact design. This also eliminates the need for special base plate mountings, couplings or complicated drives. This pump can also accept standard large flange C face IEC metric motors with feet in 71, 80 and 90 L frame sizes. Bracket codes are C1 for a 56C frame motor mount Adapter bracket, C2 for a 143TC/145TC frame motor mount Adapter bracket, C3 for a IEC 71 B14 frame motor mount Adapter bracket, C4 for a IEC 80 B14 frame motor mount Adapter bracket, C5 for a IEC 90 B14 frame motor mount Adapter bracket, C6 for a 182TC/184TC frame motor mount Adapter bracket, and C7 for a IEC 100 B14 frame motor mount Adapter bracket. The motor bracket is sold separately.