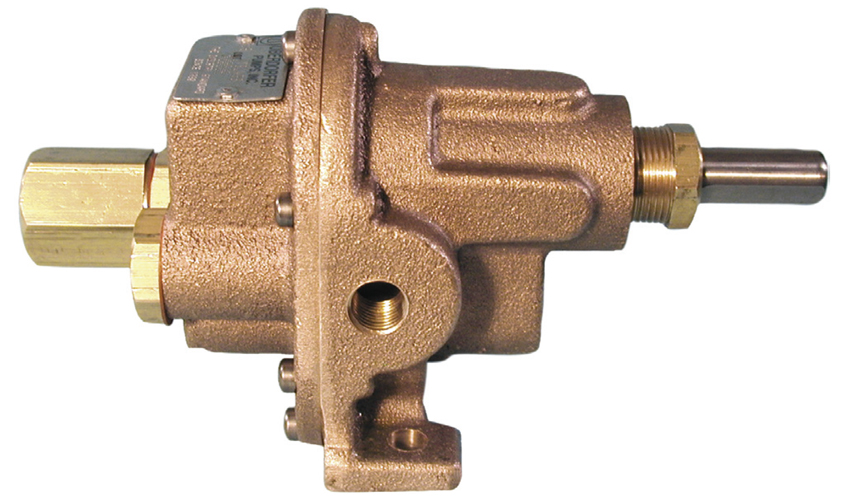

Oberdorfer # N2000R50 Bronze Gear Pump end

Oberdorfer # N2000R50

Oberdorfer catalog # N2000R50, Bronze Gear Pump end only, for mounting on a motor (motor is not included), DYNAFLUX Heliarc Welding Pump with built in Internal Relief Valve, 80 PSI, Bronze construction, Bronze Gears, Stainless Steel Shaft, Buna Mechanical Seal. Inlet Port is 1/4 Inch NPT, Discharge Port is 1/4 Inch NPT.

Price : $ 693.31

Product Information :

The Oberdorfer N2000R50 is a Bronze Gear Pump end only, for mounting on a motor (motor is not included), DYNAFLUX Heliarc Welding Pump with built in Internal Relief Valve, 80 PSI, with Bronze Gears, Buna Mechanical Seal, 1/4 Inch NPT by 1/4 Inch NPT Ports, replacement pump end only without a Motor. This pump is specifically used in Heliarc welding applications. Pump and electric motor are usually mounted on top or on the side of the coolant tank. A pressure relief valve built into the pump returns excess liquid directly to the tank rather than to the suction side of the pump, thus avoiding heat build-up in the pump. This pump is self-priming, and the maximum suction lift for this pump is 20 feet, however, the suction line should be as short as possible. A relief valve is necessary to protect the pump and system if the discharge line becomes blocked or closed. This pump has an integral built-in relief valve which is not intended to be a metering or flow control device. Its main purpose is to function as a discharge pressure relief when the spring tension is exceeded by the discharge pressure causing it to bypass internally. The relief valve is always on the discharge side in this pump series. The factory pressure setting on this relief valve is 50 PSIG. To increase bypass pressure, just turn the relief valve adjusting screw in a clockwise direction. This pump is equipped with a mechanical seal of the standard pusher bellows type or wedge style. It can be expected to provide long and trouble free service provided the seal materials are compatible with fluid being pumped, dry running is avoided, abrasives are kept away from the seal area, and the pump and driver are properly aligned. The pump has an O-ring cover seal for maximum leak protection. The bearings in this pump are designed of high performance carbon-graphite material selected for wear resistance and long service life that require no lubrication. The recommended discharge pressure limits for this pump are 100 PSI for water and non-lubricants, 150 PSI for oil and other lubricants, as the high pressure will accelerate wear. For the longest service life keep the pressure as low as possible. The maximum shaft speed is 1750 RPM. Viscous liquids require lower pump speeds and the maximum Viscosity limit is up to 50,000 SSU. This pump end does not include a motor and is just the bare shafted pump end only. Complete pump and motor assemblies can be fabricated with a pump, coupling, coupling guard, motor, and baseplate.

WEIGHT : The Oberdorfer N2000R50 weighs 7 Lbs.

Features :

Applications

The Oberdorfer N2000R50 is used in many Heliarc welding applications. Oberdorfer has a long history of supplying pumps to the welding machine industry. Ever since the Heliarc welding technology was developed, Oberdorfer pumps were used to circulate cooling liquid to the welder's torch. The reasons for the wide acceptance of Oberdorfer pumps in the welding machine industry are reliability, long service life, and ease of maintenance. This pump is being produced in quantities for several welding machine manufacturers in the U.S.A. These pumps are suitable for all liquids that are compatible with bronze. Most common liquids are water, oil, and mild chemicals in the pH range of 4 to 11. Viscous liquids require reduced shaft speeds of 1150 RPM or lower. Liquids containing solids, abrasives, powders, or paint pigments are definitely not recommended for gear pumps. If abrasives are unavoidable, use a very low shaft speed. Oberdorfer gear pumps are essentially maintenancefree. If the pump is to be shut down for an extended period of time, it should be flushed thoroughly and filled with lubricating oil. As a general rule, it is seldom economical to repair a worn out gear pump. However, if the gear chamber inside the pump body is still in good condition, the replacement of all interior parts by use of a repair kit may restore up to 80 percent of the original pump performance. Repair kit numbers and parts contained in each kit are listed on the parts lists on the reverse side.