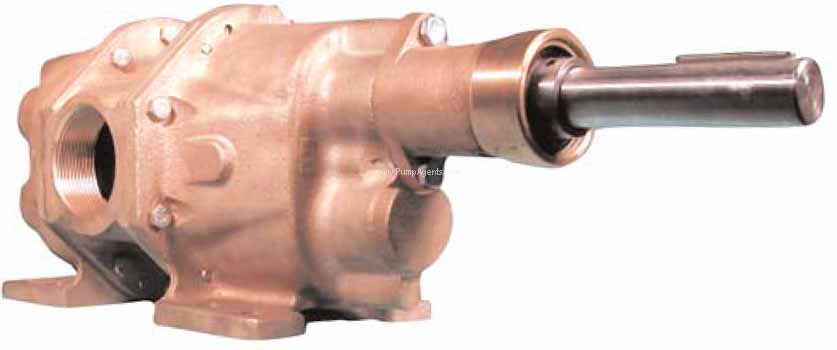

Oberdorfer # N26HDL Bronze Gear Pump end

Oberdorfer # N26HDL

Oberdorfer catalog # N26HDL, Bronze pedestal Gear Pump end only, bare shafted pump end, with Outboard Ball Bearing, Bronze construction, Bronze Gears, Bronze impeller, Stainless Steel Shaft, Viton Lip Seal. Inlet Port is 2 Inch NPT, Discharge Port is 2 Inch NPT.

Price : $ 4770.35

Product Information :

The Oberdorfer N26HDL is a Bronze pedestal Gear Pump end only, bare shafted pump end, with Outboard Ball Bearing, with Bronze Gears, Viton Lip Seal, Stainless Steel shaft, 2 Inch NPT by 2 Inch NPT Ports, replacement pump end only without a Motor. This pump is, internally, a double gear pump, with 2 drive gears and 2 idler gears, and must not be run at pump speeds above 900 R.P.M. as this will result in extreme wear. This pump can be noisy, as large gear pumps are inherently noisy due to metal to metal gear contact. Make installations far removed from office or other relatively quiet people areas. Some noise reduction can be realized by lowering pump speed and use of isolation mounts and lines, usually the small amount of noise reduction achieved does not justify the effort and expense. This gear pump can pump most common liquids, and is suitable for water, oil, and mild compatible chemicals in the pH-range from 4-10, as well as diesel fuel. The close tolerances of the gears in this pump require clean liquids with no abrasives, as abrasives will wear down the pump and cause poor performance. Gear pumps are positive displacement pumps and each shaft revolution displaces a definite amount of liquid relatively unaffected by the back pressure in the discharge line. The shaft speed and flow are directly proportional, as the flow increases with speed increase, and the power demand (horsepower) increases with shaft speed and discharge pressure. This pump is self-priming, and the maximum suction lift for this pump is 20 feet, however, the suction line should be as short as possible. A relief valve is necessary to protect the pump and system if the discharge line becomes blocked or closed. This pump is equipped with a Viton lip seal with a metal case, that are spring energized, and single lip type. These are intended to provide minimum friction drag with positive sealing. These lip seals are easily replaced by pressing out the old seal and pressing in a new replacement. The pump has an O-ring cover seal for maximum leak protection. The bearings in this pump are designed of high performance carbon-graphite material selected for wear resistance and long service life that require no lubrication. The recommended discharge pressure limits for this pump are 100 PSI for water and non-lubricants, 150 PSI for oil and other lubricants, as the high pressure will accelerate wear. For the longest service life keep the pressure as low as possible. The maximum shaft speed is 900 RPM. Viscous liquids require lower pump speeds and the maximum Viscosity limit is up to 50,000 SSU. This pump end does not include a motor and is just the bare shafted pump end only. Complete pump and motor assemblies can be fabricated with a pump, coupling, coupling guard, motor, and baseplate.

Features :

Applications

There are many applications that the Oberdorfer N26HDL are used in. These pumps are suitable for all liquids that are compatible with bronze. Most common liquids are water, oil, and mild chemicals in the pH range of 4 to 11. Liquids containing solids, abrasives, powders, or paint pigments are definitely not recommended for gear pumps. If abrasives are unavoidable, use a very low shaft speed. Oberdorfer Pump housings and gears are made of top quality bronze, shafts are 303 stainless steel. Bearings are designed of high performance carbongraphite material selected for wear resistance and long service life. These features make Oberdorfer pumps your best choice to keep your engines running longer and more efficiently. This pump is also the best solution for General Water Service, Chilled and Hot Water Systems, HVAC Industrial Processes, Municipal Drinking Water, Sprinkler and Irrigation Systems. NOTE Thick or viscous liquids are not recommended for centrifugal pumps. Because centrifugal pumps are more efficient at higher shaft speeds, pumping of viscous or thick liquids is difficult. It is possible to lose as much as 40 percent pump performance when attempting to pump liquids of viscosity equal to S.A.E. 30 oil at room temperature. S.A.E. 30 oil at room temperature has a viscosity of 2000 Saybolt Seconds Universal.