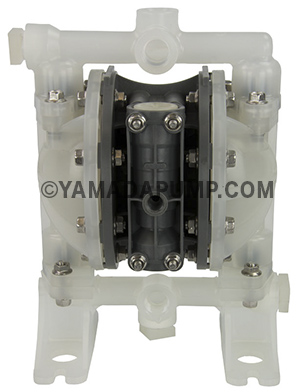

Yamada # G15PN11 Air Operated Double Diaphragm Pump

Yamada # G15PN11

Yamada catalog # G15PN11, Catalog # 854981, Air Operated Double Diaphragm Pump and Air Motor unit, with Pure Polypropylene Body construction, Buna-N Diaphragm. Inlet Port is 1/2 inch tapped FNPT, Discharge Port is 1/2 inch tapped FNPT.

Price : $ 524.40

Product Information :

The Yamada G15PN11 is a catalog # 854981, Air Operated Double Diaphragm Pump and Air Motor unit, with Pure Polypropylene Body construction, Buna-N Diaphragm, and 1/2 inch tapped FNPT Ports. The Yamada G15 Pure Polypropylene series AODD pumps provide a maximum flow rate of 16.6 GPM and are available in Aluminum, Stainless Steel (316), Pure Polypropylene and Kynar. Yamada Global Series pumps do not have an independent pilot valve system (less parts) and consume less air versus the competition. Available with multiport options, these AODD pumps perform extremely well in continous stop/start operations and provide exceptional suction lift.

WEIGHT : The Yamada G15PN11 weighs 9 Lbs.

Features :

Applications

There are many applications that the Yamada G15PN11 are used in where a flow rate of up to 16.6 Gallons Per Minute is required. Typical applications for this pump include Filter Presses, adhesives, paints, chemical additive, winery pump over transfers, general wastewater transfer, drum pumps, tanker unloading, spraying, dosing, pigments, colorants, flavorings, filling machines and mixing tanks all use diaphragm pumps to manage their fluid handling systems. Common fluids pumped with the Yamada G15PN11 include industrial paints, polymers, hardeners, varnishes, lacquers, greases, adhesives, latex, acids plus bases and titanium Dioxide or fumed silica powders that require mixing and blending at various temperatures and flow rates. Some of the most common acids pumped are Hydrofluoric, Sulfuric and Nitric. Some of the most common finished products pumped are wines, paints and various adhesives or coatings. A double diaphragm pump can continuously transfer single or plural components through the up and down stream avenues of a fluid handling system. An air operated double diaphragm pump is typically used where air is readily available, and the characteristics of the application are better suited for the technology. If you have solids, a thicker liquid, selfpriming requirements, dry running potential, explosion proof specs, variable flow rates, shear sensitive liquids, something submerged, portability required, or the application calls for dead heading, then a diaphragm pump is an excellent choice. Things like sumps, tanker unloading, and simple water or chemical transfer applications are the most common and basic. There are process or more challenging applications for the technology also in industries like carpet manufacturing, paint plants, pharmaceutical facilities, semiconductor fabs, the printing industry and powder transfer. Each application will have their own requirements and the pumps can be modified accordingly to achieve the flow rates required while also maintaining long pump lives.